Many facility owners and engineers assume pre-insulated pipe supports are only necessary for extreme temperature applications such as cryogenic or high-temperature steam lines. However, even when a pipe’s surface temperature feels “not that hot or cold,” pre-insulated supports can provide significant benefits in safety, efficiency, and long-term reliability. This article will help you understand the various types of pre-insulated pipe supports available, so you can select a solution that provides the necessary protection without over-engineering or overspending.

Why Pre-Insulated Pipe Supports Matter

1. Preventing Thermal Bridging

Moderate-temperature fluids can create temperature differences between pipes and supports. Without insulation, the support acts as a thermal bridge, causing heat loss or condensation, leading to increased energy loss, corrosion under insulation (CUI), and inconsistent system temperatures.

2. Controlling Condensation

When pipes are cooler than ambient air (e.g., in chilled water or HVAC lines), condensation can occur. This results in dripping hazards, mold, and corrosion of structural steel and hangers. Even pipes at 50–60 °F (10–16 °C) can sweat in humid conditions.

3. Maintaining Process Stability

For temperature-sensitive processes, small fluctuations impact product quality or efficiency. Pre-insulated supports ensure stable temperature profiles throughout the line.

Design Considerations: Selection Guide

1. Proper Support Selection

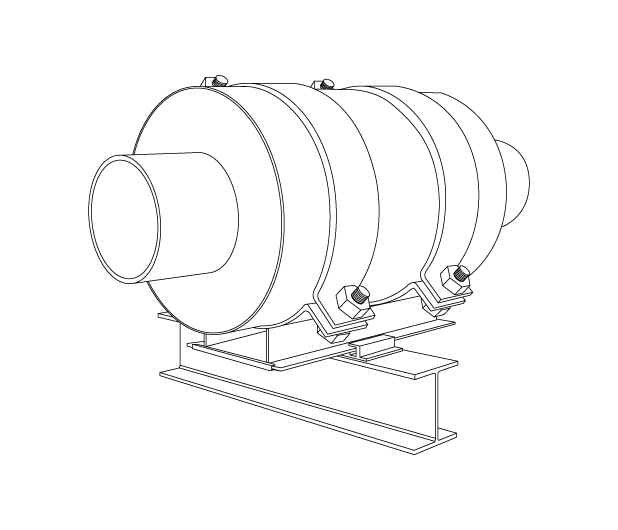

- Pre-Insulated Pipe Shoes: Provide load-bearing insulation while elevating the pipe to prevent moisture accumulation and protect against corrosion.

- High-Density Inserts: Distribute the load while minimizing insulation compression.

- Vapor Barriers: Essential for chilled or sub-ambient lines to prevent moisture ingress.

2. Material Choices

- Polyurethane Foam (PUF): Good for chilled water and moderate cold applications.

- Calcium Silicate or Mineral Wool: Suitable for moderately hot lines

- Phenolic Foam or Aerogel: Lightweight options with superior thermal resistance.

3. Installation Tips

- Ensure continuous insulation without gaps at support points.

- Use proper cladding or jacketing to prevent water intrusion.

- Verify the compressive strength of insulation matches the pipe load.

Practical Examples

Selecting the correct pre-insulated support involves matching the support type to the temperature and load requirements of your application.

Don’t let temperature fluctuations undermine the performance of your entire system. Choosing the right pre-insulated pipe supports is a wise investment that pays for itself through energy savings and reduced maintenance costs.

| Application | Fluid Temp Range | Reason for Insulated Supports |

| Chilled Water HVAC Lines for datacenters, Semiconductor fabs, and Pharmaceuticals | 40–55 °F (4–13 °C) | Prevent sweating and corrosion |

| Mild hot-water process lines | 120–180 °F (49–82 °C) | Energy efficiency and personnel safety |

| Food & Beverage pipelines | Ambient to 150 °F | Sanitary conditions and temperature control |

Key Takeaways

- “Not that hot or cold” does not mean insulation is unnecessary.

- Pre-insulated pipe supports prevent condensation, energy loss, and corrosion, protecting both your system and personnel.

- Proper materials, design, and installation are crucial for long-term performance.

Recommended Action. Evaluate every piping system, regardless of temperature, for potential thermal bridging, condensation risk, and process stability issues. Consult insulation and support manufacturers to specify the right product for your application.

Partner with Piping Technology & Products and Pipe Shields for Pre-Insulated Pipe Supports

Every new project brings the challenge of coordinating materials, managing complex engineering challenges, and preparing for unexpected delays. Rapid Response really looks like ingenuity, flexibility, and execution under pressure.

Pipe Shields Inc. pioneered the design and manufacture of pre-insulated pipe supports, slides, guides and anchors and is a subsidiary of Piping Technology and Products, Inc. Our products are ubiquitous, serving diverse industries including hospitals, airports, semiconductor plants, automotive plants, EV battery plants, data centers, pharmaceutical plants, food processing, petrochemical plants, and power and renewable energy plants sometimes used in cold service lines and some dual temp lines between TCUs (temperature control units) and reactor jackets. Engineers often specify Pipe Shields and PT&P products as the foundation for designing various piping systems.

Since last year, our Houston manufacturing facility has produced over 100,000 units of this support, demonstrating our capacity and reliability. We were the first in the industry to employ the use of high-speed manufacturing automation to facilitate the cutting of the high-density calcium silicate to meet tight deliveries required for the projects. The advent of computer-controlled cutting equipment has significantly improved our manufacturing processes at PT&P. By integrating these advanced technologies, we have achieved substantial enhancements in manufacturing operations, enabling unparalleled accuracy in cutting high-density insulation. Computer-controlled cutting equipment allows for intricate and complex designs that were once challenging or impossible to achieve manually. Automating cutting processes has not only reduced human error but also enhanced productivity by accelerating production speeds. Moreover, these systems provide a high level of repeatability, ensuring consistent quality across multiple iterations. This technology has also reduced material waste by approximately 10–15% compared to human cutting, allowing us to remain highly competitive in global pricing.

With in-house engineering and a massive scale manufacturing capacity, we deliver seamless, end-to-end solutions with flexibility, ingenuity, and timeliness.. And when you need a rapid response,, our 24/7 emergency line is like no other, solving is solving unforeseen challenges in hours, Ready to protect your investment with pre-insulated supports? Get a customized quote for your next project.

Read More