PTP Smart Maintenance Solutions – Providing the Best Value and Most Advanced Capabilities in Piping System Services.

What uniquely qualifies PT&P to service your Piping System is our depth of expertise:

- Over 3M Piping System parts currently deployed Globally

- 50+ Piping Design Engineers

- 500 Production Employees, including 20+ Production Engineers, prepared to support Smart Services business

- Deeply experienced services leadership team with over 100 years of combined experience

- Over 500 Field Services jobs completed globally supporting most major Petrochem, Power, and Chemical Companies

Our experience in the field shows that Piping Systems are an underserviced area of the plant that often does not receive the focus and experience required to maintain optimal long-term performance. Some examples of projects we have conducted this year include:

| Issues | Description of Problem | Corrective Action Taken |

|---|---|---|

| Installation deviation | Supports were installed in wrong location especially because they looked very similar and contractor failed to identify the right supports to be installed in right location | Identified during assessment. Have our crew replace back to the original design position. |

| Spring Supports Locking Device (Travel stop) | A common problem where Installation contractors failed to remove the travel stop resulting pipe stress and eventually causing crack and other issues. | Identified and made a report with list of supports with travel stop in. With the help of our crew, we have removed the travel stop and adjusted the support to proper settings. |

| Alignment problems | Due to lack of adjustment to proper settings, there are several cases where pipes are misaligned and are off from their design elevation. | Compared the elevation of the pipe with the isometric drawings. Adjusted the existing supports, or even have done the load testing to redesign new supports with new loads to properly align the pipe and bring back to original elevation. This has solved the issue of water hammer as the proper elevation helps to maintain the proper draining of the excess water/fluids. |

| Holes or tears on expansion joints | Contractor failing to install the fabric expansion joints properly by not letting the fabric EJ to expand through the design movement. | Our field engineers identified the problem. With the help of design engineers, we redesign the fabric EJ and install with extra materials to allow the design movement. |

| Improper installation of Tie-rod of Metal Bellows | Contractor failing to adjust the tie rod to allow the anticipated movement. | Our crew has identified the issue and adjusted the tie rod as per the design. |

| Lack of database for pipe supports | Common occurrence where the plant doesn’t have the database of all the supports and their design specification. | We have assess the pipe supports, took all the readings from the supports tag, take necessary dimension when required, to create pipe supports database. Database will have space to record the historical data of the supports for future. |

| Overloaded supports | The changes in the line occurs more frequently such as adding new valves or replacing the valves with different weight resulting issue like bottomed out or topped out supports, misalignment. | We have identified such issues during audit, and have done stress analysis to determine new load condition. In some cases where the stress analysis is not possible due to time constraint, we have used crane scale to determine the approximate weight of the line to design new loading condition. |

| Damaged insulation | Some pre-existing shoes (cold shoe, hot shoe) had damaged insulation. Sometimes, the shoes are in reducers resulting very hard to reverse engineer for inexperienced contractor. | We have field measured the shoe and insulation, discussed remotely with design engineers and came up with accurate design. We have re-installed the shoes. |

| Improper shoe installation | The high density insulation that was designed to go below pipe and low density insulation that was designed to go above were upside down. The metal jackets weren’t installed properly to keep up moisture. | Recently field engineers went to a new construction site to examine ongoing installation and found 90% of shoes had some issues during installation. They trained all the workers, supervisors to properly install the shoe and made them aware of implication of improper installation. We have also done several installations of shoes as required. |

| Corrosion and Fatigue Related Failures | Pipe supports and piping system components suffering failure due to corrosion and fatigue. For example: Bottoming out of spring supports, rusted components | Identified the failure based on the age and the functionality of the supports and other components. They were either repaired by replacing corroded parts or total swap with new materials. |

| Supports and components failure without drawings | Some supports and components have failed such as holes in expansion joints that lack the drawings to replace in kind. This is common for 20+ years old components. | We have reverse-engineered the products which doesn’t have specification and drawings. We have incorporated new technology on these designs. |

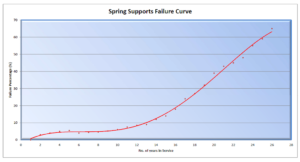

The need for expertise in maintaining piping systems has never been greater. PTP is routinely providing service to plants that are 40+ years old. The chart below is a compilation of our experience in projecting failure rates by plant age. As can be seen from the chart, plants that are older become highly likely to start experiencing issues in the Piping System. With the right expertise and experience, these plants can leverage a proactive preventative approach to maintenance to prevent unexpected outages or having piping issues that result in damage to sensitive equipment.

We have completed thousands of projects with many major players in the Oil and Gas, Power, and Chemical industries. We can provide services on a individual project basis and as an extremely cost-effective on-site presence that can increase the level of expertise in Pipe Supports and Piping Systems in your day to day operations. Services we offer include as part of our Smart Services portfolio include:

- Smart Maintenance

- Installation

- Diagnosis and Repair

- Audit/Inspection

- Turnaround Planning and Support

Smart Maintenance

PTP is the first company to apply sensors and machine learning to the ongoing monitoring and preventative maintenance of Pipe Supports. We are working directly with Ericsson, one of the world’s largest telecom equipment companies, to ensure our product is using the latest design and we have an eye towards upcoming changes in the capabilities of plant level communications. Our Smart Maintenance solutions can be deployed on either a new build or retrofit of an existing plant. In addition, for retrofits, we work with not just our own supports, but also with any other provider’s supports.

Based on our internal work and work with Ericsson, we have created designs for Constants, Variables, and Bellows. Our designs involve the monitoring of both the support itself as well as the temperature of the Pipe. This allows to not only see if the support has failed but also to see if there is a variance to historical behavior (change in the level of movement with a given temperature of the pipe being supported) which indicates fatigue, corrosion, or another issue which must be investigated. See the attached link for a presentation on our smart maintenance solutions that include designs for our use of sensors as well as a summary of our Artificial Intelligence capability.

Diagnosis and Repair

As a designer and manufacturer of pipe supports and piping system components, we have deep expertise that makes PTP very skilled in troubleshooting and reverse engineering in order to diagnosis and develop solutions for any issue you may have in your Piping System. In addition, we are on call and available to travel 24/7 so we can help with an issue no matter how urgently a solution is required. An example of this is we recently helped a customer who was in the middle of an unplanned outage due to a expansion joint failure. The plant was over 50 years old so there was very little documentation for the expansion joint or Piping System. We went on-site to begin in our diagnosis and then worked tirelessly with the customer to reverse engineer the requirements and develop and deliver an expansion joint that would work for the plant. This included the customer coming on-site to PTP in Houston and working face to face with both our design engineering and production team for expansion joints and PTP going back to customer site to ensure proper installation and functioning of the new Expansion Joint. The teamwork between the customer and full range of PTP personnel led to a rapid solution in a few days that resolved the outage.

Installation

PTP has supported the installation of Piping Systems all over the world. As a designer and manufacturer of Piping System Components, we are deeply familiar with the proper installation and functioning of a piping system. Throughout our 40 years of experience in the Piping Industry, we have seen many issues related to a faulty initial installation. By leveraging the expertise our expertise, you can ensure that your system is installed correctly the first time. This can be during initial plant construction or the installation of replacement parts during a turnaround.

Audit/Inspection

PTP has deep expertise in the audit of power generation and chemical plants as well as refineries. We have not only inspected hundreds of plants, but also have learnings from having over 3M Piping System Parts and Pipe Supports currently in deployment globally. We are available to conduct an audit in as little as 24 hours (or less) and are available 24/7 by phone.

Turnaround Planning and Support

PTP has worked with many customers to prioritize findings from an audit in order to prioritize and plan repair activities to be done during a turnaround. In addition, our work in Pipe Supports over the last 40 years has shown one of the biggest issues with supports is improper installation. As a result, many customers find our services during a turnaround, PTP support to ensure proper installation and functioning of new supports to be invaluable to achieving the desired result of the repair/replacement.

Schedule a Lunch and Learn and Complimentary 1 Day Audit

We are now offering a complimentary Lunch and Learn and 1 Day audit at your site. The PTP Smart Maintenance group will come to your site and educate you on the use of the latest sensors and artificial intelligence on preventative maintenance for Pipe Supports along with an overview of key technical considerations for the proper functioning and maintenance of different types of Pipe Supports. We will also do an audit of an area of the plant and provide a report on the findings and what it means for your plant.