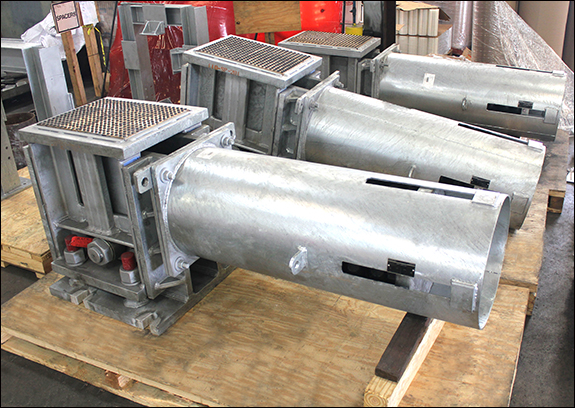

CUSTOMIZATION: Spring Supports

|

|

|

|

Materials

|

|

|

Finishes

|

|

|

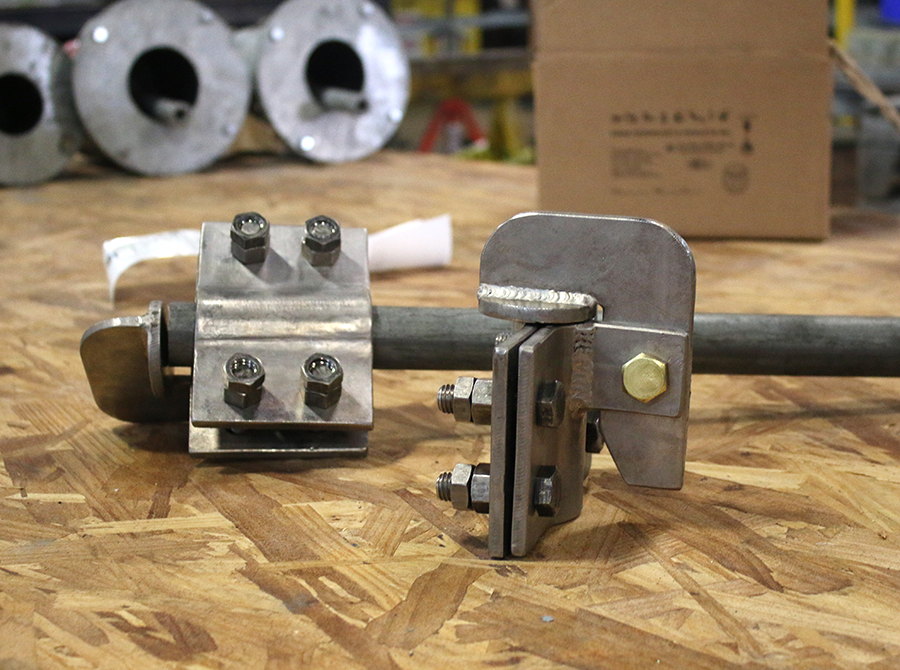

DimensionsThe size can be optimized to specific dimension requirements, and customized to fit in restricted spacing. |

|

|

LoadWe can supply spring supports with custom load capabilities of Load AdjustmentStandard is +/- 10%, but we can customize up to +/- 60% Load Adjustment) |

|

|

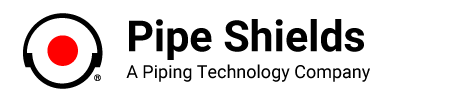

TravelStandard is +/- 10%, but we can customize up to +/- 60% Load Adjustment) Travel StopsWe can provide wire or chained travel stops. |

|

|

Sensors for Remote MonitoringWe can provide sensors on spring supports to monitor the conditions remotely, and give warning alerts whenever a support does not perform as it should. |

|

|

Unparalleled Customization from Unmatched Manufacturing Capabilities

PT&P has developed a unique approach to its manufacturing operation that produces the broadest set of customization options with minimal impact to delivery timeframes. Most producers operate as smaller scale steel fabricators or highly standardized mass production organizations. PT&P is the only organization that is set up for both scales with over 500 production employees, customization capabilities, and artisan manufacturing skills. For example, PT&P is the only Major Global Supplier of both Expansion Joints and Engineered Pipe Supports. This unmatched manufacturing technique was achieved through proprietary systems, a highly engineered approach to manufacturing, and incorporating 10+ Industrial Engineers in the production operation.

Manufacturing Approach for Pipe Support/Expansion Joint Manufacturers

| Steel Fabricator (Owner/Operator) | Mass Production | PT&P Mass Customization | |

| Machinery | Simple | Scale | Scale and Artisan |

| Advanced Skills (e.g. TIG welding Inconel) | Varies | Limited | Yes |

| Systems | Limited | For Mass Production | Advanced Systems allow Management of Complexity |

| Customization/Flexibility | High | Low | High |

| Short Turnaround | Yes | No | Yes |

| Scale | Low | High | High |

| Outsourced Offshore | No | Yes | No |

| Engineering Knowledge | Low | Medium | High |

| Ability to Manage Contamination Across Materials | ? | No | Yes |

| Breadth of Product Line | Medium | Low/Medium | Large |

| Target Customer | ? | Major EPCs | All |