Installation Steps

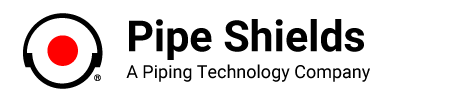

1. Position bottom half of the insulated shield into the base assembly. Ensure that the inserts are properly located over the strap by checking that:

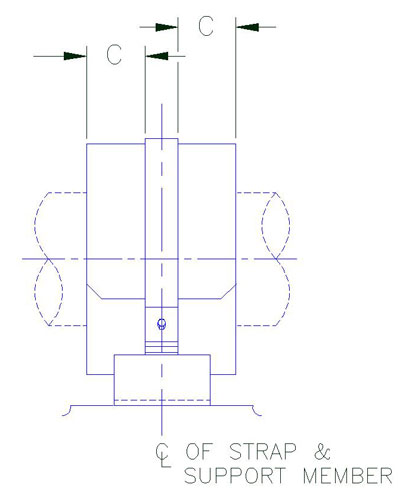

A) Each end of shield shall have equal distance (C) from outer edge of strap (Figure A).

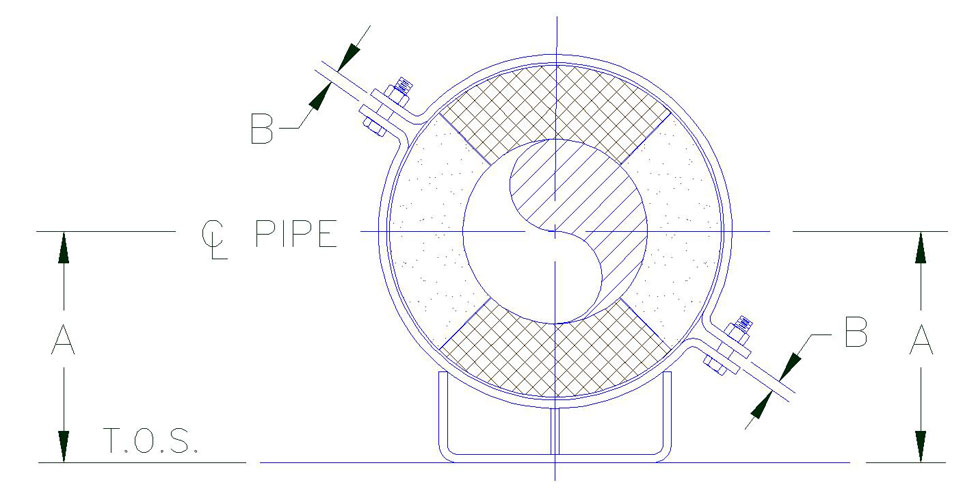

B) The 180° section of the bottom half shield shall be parallel to the support base (Figure B).

Slide the base assembly and insulated shield into position under the pipe at the applicable support location.

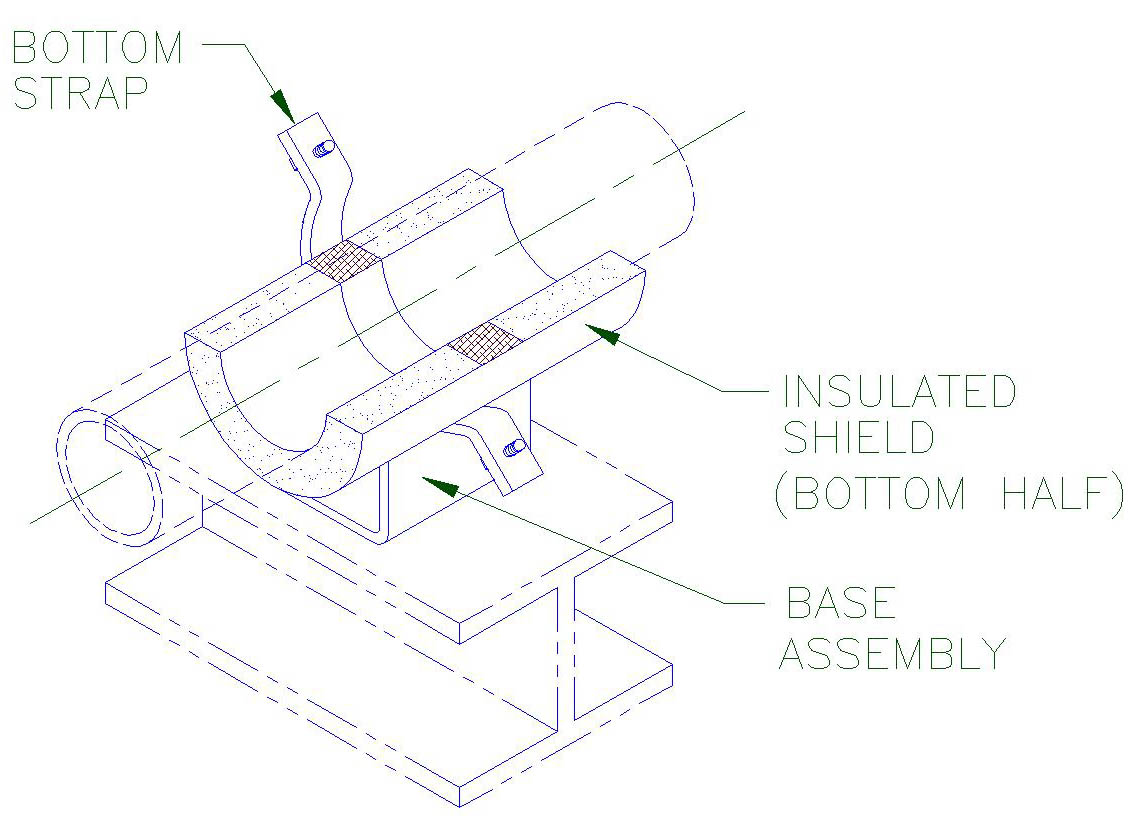

2. A) Lower the pipe onto the bottom half of the shield.

B) Slide the top shield into position.

C) Gently place the top strap into position above the bottom strap as shown and line up the bolt holes.

3. A) Install the bolts, lockwashers and nuts and hand tighten. For ease of bolt torquing, install the bolts with the nuts on top.

B) Apply torque on the bolts. Select torque value that correspond with the pipe size and model designation of the unit shown on Table 1. When tightening, it is recommended that the nut is turned rather than the bolt head and that the bolts are cross-torqued until the required torque has been achieved to obtain an even pressure on the structural insulation.

C) Ensure that the bolts are properly cross-torqued by checking the spacing “B” between the ears to be approximately the same (see Figure B).

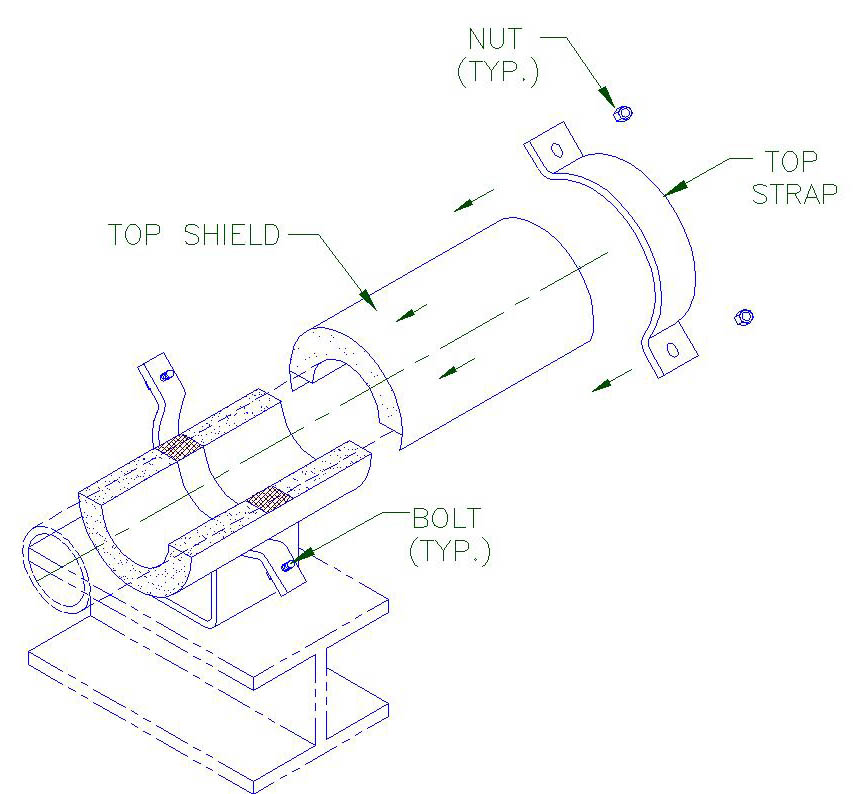

4. When properly positioned, weld base assembly to steel support as shown. Select “W” (weld size) that correspond with the pipe size and model designation of the unit shown Table 1.

| Table 1

Bolt Torque & Weld Size (W) |

||||||||

| Pipe Size | ||||||||

| Bolt Torque (FT-LBS) |

Weld (W) Size | Bolt Torque (FT-LBS) |

Weld (W) Size | Bolt Torque (FT-LBS) |

Weld (W) Size |

Bolt Torque (FT-LBS) |

Weld (W) Size | |

| 1″ | 3-5 | 3/16″ | 3-5 | 3/16″ | 3-5 | 3/16″ | 3-5 | 3/16″ |

| 1.5″ | 3-5 | 3/16″ | 3-5 | 3/16″ | 3-5 | 3/16″ | 3-5 | 3/16″ |

| 2″ | 3-5 | 3/16″ | 3-5 | 3/16″ | 5-7 | 3/16″ | 3-5 | 3/16″ |

| 2.5″ | 3-5 | 3/16″ | 3-5 | 3/16″ | 3-5 | 3/16″ | 3-5 | 3/16″ |

| 3″ | 3-5 | 3/16″ | 3-5 | 3/16″ | 3-5 | 3/16″ | 3-5 | 3/16″ |

| 3.5″ | 3-5 | 3/16″ | 3-5 | 3/16″ | 8-10 | 3/16″ | 3-5 | 3/16″ |

| 4″ | 4-6 | 3/16″ | 7-9 | 3/16″ | 10-12 | 3/16″ | 7-9 | 3/16″ |

| 5″ | 4-6 | 3/16″ | 9-11 | 3/16″ | 13-15 | 3/16″ | 9-11 | 3/16″ |

| 6″ | 7-9 | 1/4″ | 13-15 | 1/4″ | 20-22 | 1/4″ | 13-15 | 1/4″ |

| 8″ | 9-11 | 1/4″ | 18-20 | 1/4″ | 27-29 | 1/4″ | 18-20 | 1/4″ |

| 10″ | 10-12 | 1/4″ | 21-23 | 1/4″ | 31-33 | 1/4″ | 21-23 | 1/4″ |

| 12″ | 11-13 | 1/4″ | 23-25 | 1/4″ | 34-36 | 1/4″ | 23-25 | 1/4″ |

| 14″ | 13-15 | 1/4″ | 26-28 | 1/4″ | 39-41 | 1/4″ | 26-28 | 1/4″ |

| 16″ | 18-20 | 1/4″ | 36-38 | 1/4″ | 54-56 | 1/4″ | 36-38 | 1/4″ |

| 18″ | 20-22 | 1/4″ | 40-42 | 1/4″ | 60-62 | 1/4″ | 40-42 | 1/4″ |

| 20″ | 21-23 | 1/4″ | 43-45 | 1/4″ | 64-66 | 1/4″ | 43-45 | 1/4″ |

| 24″ | 23-25 | 1/4″ | 45-47 | 1/4″ | 68-70 | 1/4″ | 45-47 | 1/4″ |

| 26″ | 20-25 | 1/4″ | 50-52 | 1/4″ | 75-77 | 1/4″ | 50-52 | 1/4″ |

| 28″ | 27-29 | 1/4″ | 54-56 | 1/4″ | 81-83 | 1/4″ | 54-56 | 1/4″ |

| 30″ | 39-41 | 1/4″ | 78-80 | 1/4″ | 118-120 | 1/4″ | 78-80 | 1/4″ |

| 32″ | 41-43 | 1/4″ | 82-84 | 1/4″ | 123-125 | 1/4″ | 82-84 | 1/4″ |

| 36″ | 46-48 | 1/4″ | 92-94 | 1/4″ | *138-140 | 1/4″ | 92-94 | 1/4″ |

| 42″ | 52-54 | 1/4″ | 103-105 | 1/4″ | *155-160 | 1/4″ | 103-105 | 1/4″ |

* = Requries A-325 Bolt Material